“We need to be more responsible about the environment, the economy, the people. Because now more than ever it is more than a necessity it is an emergency” – Dr.Carmen Hijosa

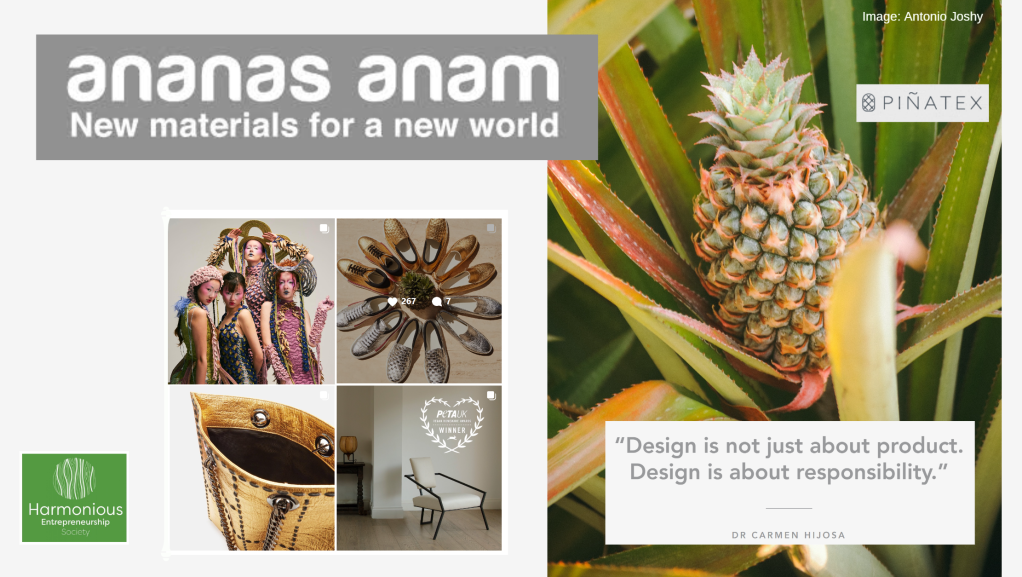

In India, Fleather, a leather substitute, is being made from discarded temple flowers, while in the Philippines, a similar product, Pinatex, has been developed from waste pineapple leaves by a London headquartered company, Ananas Anam. Incorporated in 2013, the company was founded by Dr Carmen Hijosa, its current Chief Creative and Innovation Officer. A graduate of Dublin’s National College of Art and Design and the Royal College of Art in London, Dr Hijosa was shocked by the negative environmental impact of mass leather production and chemical tanning, coupled with the toll it took on people’s health. So, she embarked on a programme of research that resulted in the creation of Pinatex and the launch of Ananas Anam through the Royal College’s high growth incubator programme, Innovation RCA.

Initially, she was inspired by such natural materials as Jusi, used to make the delicate translucent Philippino national Barong Tagalog garments. This material is woven from the fibres of Manila plantain and pineapple leaves, and Dr Hijosa began to wonder whether it might be possible to replace leather with a plant-based textile that could be commercially produced, would have a positive economic and social impact, and would generate a low carbon footprint. It took seven years for her to develop Pinatex and launch Ananas-Anam, but when she did, she had created out of a waste product a material that created jobs in rural areas and provided a second income stream for the pineapple farmers.

Traditionally, after the pineapple crop had been harvested, the plant and its leaves were either burned or allowed to rot down. With the invention of Pinatex, the fibre is extracted from the leaves, giving the farmers a second income, and the biomass that remains is composted. The fibres are then dried naturally, whenever possible, and purified before being mixed with a corn-based polylactic acid to produce a non-woven mesh, Pinafelt, which is then shipped to Italy or Spain for finishing and turning into Pinatex. This is used by over 1000 brands worldwide and turned into a variety of products, including bags, clothes, shoes, upholstery and wallets As a consequence, the amount of CO2 released into the atmosphere is reduced as each kilo of Pinafelt prevents up to 6kg of CO2 being emitted, while each linear metre of Pinatex prevents the emission of the equivalent of a further 12 kg of CO2.

While Pinatex has passed all of the same tests as leather and has been adopted by Nike, for example, Dr. Hijosa advises to forget leather, and she should know as she worked with it for 15 years. Rather, she sees Pinatex as a completely new product that should be treated as such. However, she acknowledges that whereas initially the leather producers thought her ideas were absurd, they are now recognising that leather is not sustainable and are beginning to want to collaborate with her. As she also recognises all that has been achieved in the Philippines can be replicated elsewhere, wherever they grow pineapples. So she is confident that Pinatex will be able to launch a revolution that will both help reduce inequalities and save the planet and its people.

Dr.Hijosa has become a recognised creative leader, having won, for example, the Cartiers Women’s Initiative Award (for sustainable innovation) in 2015 and in 2016, the Innovate UK Women in Innovation Award (for sustainable materials). In 2020, Ananas Anam became a certified BCorp with a score of 80.5, being known particularly for treating everybody fairly, whether they are the factory workers or the pineapple farmers. As Dr.Hijosa says “We know everybody in our supply chain. We know where the fibres come from. We know the farmers. This is a privilege”. Very much a Harmonious Enterprise that embraces profit, planet, and people, Ananas Aman addresses SDGs 1 (No Poverty), 8 (Decent Work and Economic Growth), 9 (Industry, Innovation, and Infrastructure), 10 (Reduced Inequalities), 11 (Sustainable Cities and Communities), 13 (Climate Action), 15 (Life on Land), and 17 (Partnerships for the Goals).

© Harmonious-Entrepreneurship.org / Harmonious Entrepreneurship Ltd. (2020-2023).

Without talented, innovative and creative people like Dr Hijosa the manufacturing industries would not diversify or look for more sustainable solutions to every day problems. Pinatex has impressive credentials – providing secondary income to producers, addressing waste and bringing alternative products to the major brands. May their success continue and perhaps in the longer term Pinatex will manufacture the finished products closer to source, thus reducing transport costs and carbon footprint.

LikeLike

See my comments above

LikeLike

This is very interesting! I was researching about the Pinatex trademark as I came across the Inditex line which the Zara brand belongs, they have this line under the Sustainability Innovation Hub in which they use a fabric made from Piñatex. I have been very interested in researching about the probability of a cloth made from Taro leaves which is abundant here in our province Albay, Bicol Region particularly the diverse variants of giant heart-shaped leaves abundantly growing down the slopes of the Majestic Mount Mayon Volcano. The green leaves is famous as the main ingredient of Bicol’s Laing and Pinangat of Camalig as well as Pinangat and Laing made from the Budiao Apay of Daraga. If there could only be student researchers who could help in Taro Leaves sustainable innovation as a textile material, the locales here in our municipality will have a chance to have a debut in the global market and could make it through big and international clothing brands such as the Inditex Group, Zara, Gap, Uniqlo and other well known brands.

LikeLike